Battery Testing Control and Safety System

Company: VSK Test Solutions

Author(s): Mr. Parth Joshhi, Miss Sabrine Charkaui, Miss Sirine Charkaui

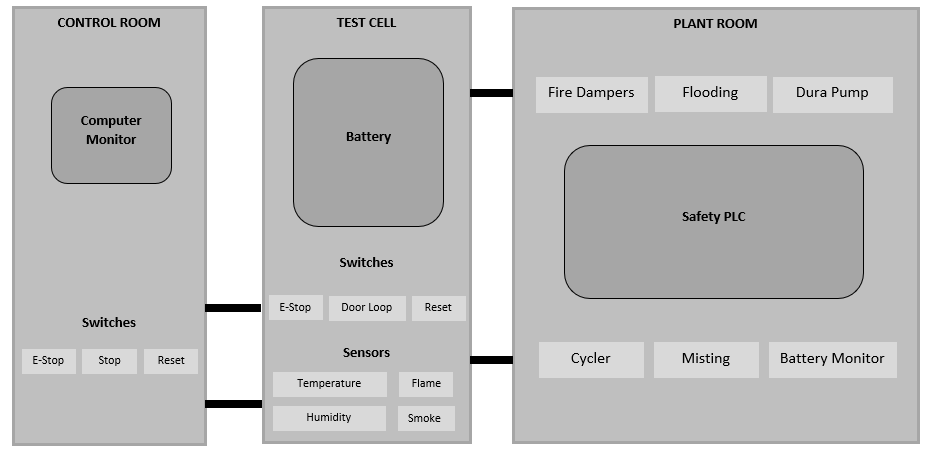

Product(s) Used: Safety PLC (M1S, MOS16, MI16), Sensors

Software(s) Used: ReeR Mosaic Safety Designer

Industry: Automotive EV

The Challenge

The design and development of a safety system to monitor and control a lithium-ion battery and start a fire suppression procedure if smoke or fire is sensed.

The Solution

Used a Safety PLC with ReeR Mosaic Safety Designer to monitor a lithium-ion battery with sensors and control the temperature and potential fires through a safety system. This safety system includes misting, flooding, and fire dampers with sounding alarms to alert when there is a fire. The status of the lithium-ion battery can be viewed in a control room through a computer monitor with buttons in case of danger.

Introduction

VSK Test Solutions was established in 2015 in order to provide consultancy services for test development in various domains like telecommunication, green energy, aerospace, and smart metering.

The Battery Testing Control and Safety System includes buttons with cyclers, sensors/monitors, and safety equipment such as misting, flooding, and fire dampers to suppress a potential fire.

Application Description

Multiple tests are carried out to ensure the battery is stable, this includes:

- Performance Testing – We test battery packs and modules for their capacity, energy density, cycle life, and other performance metrics to ensure that they meet or exceed the required standards.

- Safety Testing – Battery safety is a top priority, and we perform a range of tests to ensure that battery packs and modules are safe to use and transport. These include abuse tests such as shortcircuit, overcharge, and impact tests, as well as tests for thermal stability and flammability.

- Environmental Testing – We subject battery packs and modules to a range of environmental conditions to assess their performance and durability under extreme temperatures, humidity, vibration, and other environmental stresses.

- Compliance Testing – We help our clients comply with relevant regulations and standards, such as UL, IEC, and ISO, by testing battery packs and modules to meet these requirements.

- Endurance Testing – We perform extended charge-discharge cycling to assess the durability and longevity of the battery pack or module.

- BMS Testing – We test the battery management system (BMS) for proper functionality and communication with the battery pack or module.

Impact/Results

This solution provided by VSK Test Solutions is a critical safety system because of its high voltage and current when testing the battery. This system runs overnight and so temperature testing is highly important with the change in environment.

Conclusion

The client can now run battery testing with a wide range of sizes and capacities for longer runs with the assurance of safety.

Author Contact Details

VSK Test Solutions

Unit 16 & 20 Space Business Centre

Smeaton Close, Aylesbury

Buckinghamshire HP19 8FJ

Email: sales@vskconsultants.com

Website: https://www.vskconsultants.com/

Phone: +44 (0) 1296695548